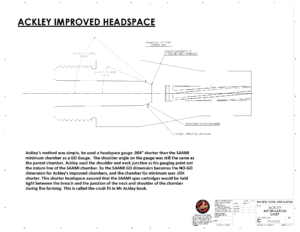

In volume 1 of P.O. Ackley’s “Handbook for Shooters and Reloaders” Ackley explains headspace for his improved designs as well as standard factory cartridges. The chapter describing these details starts on page 151 of that book. Professor Ackley is very clear about proper measurements, even explaining some history of how chambers have been measured.

When you chamber for a rimmed cartridge like the 30-30 Winchester the headspace is measured from the locked bolt face to the forward edge of the rim where it contacts the rear of the barrel. The shape of the chamber need only have enough taper so that it will reliably extract, as the case body has not relationship to headspace in this type of cartridge.

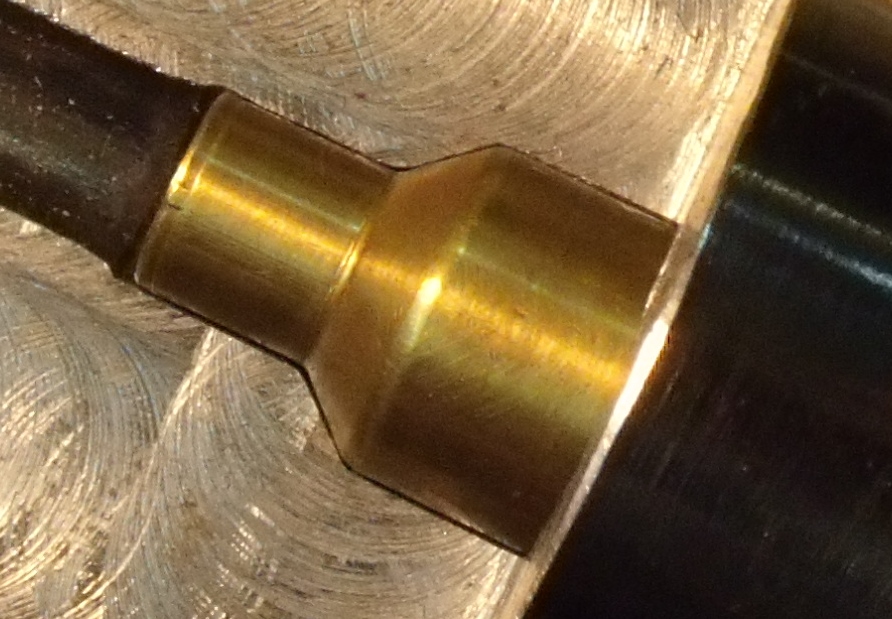

A picture is truly worth a thousand words, so note in the comparison here the drastic change in shape when a 30-30 is rechambered to 30-30 Ackley Improved.

It should be an easy leap to see that a belted magnum case would be much like a rimmed case if it were to be wildcatted or modified. The belt is the headspace feature on such cases. Specifically, the distance from the fully locked bolt face to the forward edge of the belt where it contacts the barrel is the headspace in a belted magnum. Pretty much anything you say about rimmed headspace is equally true for belted case.

Rimless cases is where people seem to get confused with Ackley Improved designs.

First, I would heartily suggest that you read Ackley in his own words as he is pretty clear on the subject. With that said, I will give an explanation in my own words. Ackley said he regretted using the term “improved” in conjunction with these designs. I understand why he said that, not all cartridge show substantial gains in velocity from the process. The resulting increase in velocity has a lot to do with the beginning case capacity and the bore capacity relationship. In other words, the greater the increased capacity the better the velocity increase. Ackley did not suggest another name for the improved concept.

For the uninitiated out there…

Rimless improved chambers, when properly headspaced, allow the shooter to fire the factory parent cartridge in the new improved (oversized) chamber safely. This is because the cartridge is headspaced on the junction of the neck and shoulder. Traditional Ackley gauges utilize a go gauge that is .004″ shorter than the factory or SAAMI go gauge. Because only a small point on the shoulder is in contact with the chamber it is easy to crush the shoulder as the bolt closes. When fired the brass stretches to fill the new improved chamber. This is what is known as fire-forming. Want to learn more details of Ackley Headspace and Chambering? Click Here.

Once fire-formed the cases can be loaded to the new potential of the Improved Chamber.

I often hear shooters try to say Ackley Improved is not worth the trouble. Clearly, that is a matter of opinion. However, most reloaders are looking for more velocity; even 50 feet per second is important to such shooters. A quick calculation of the change in case capacity will tell the shooter is there is much velocity to be gained. My personal rule of thumb is that there needs to be three percent or more increase in case capacity to see any reasonable increase in velocity.

Wildcatting is about having fun and spending more time with your hobby. Improved cartridges are a great way to ease into wildcatting. You don’t need a bunch for specialty dies to form the brass. You just fire factory cartridges in your gun and you have a new cartridge formed. Plus, it gives you that unique gun that few, if any, at the range will have.

A few cartridges that receive a real substantial boost from the Ackley Improved chamber:

- 219 Zipper

- 22-250

- 25-35 WCF

- 250-3000 Savage

- 257 Roberts

- 6.5-06

- 280 Remington

- 30-30 WCF

- 30-40 Krag

- 30-06

Interested in trying an Ackley Improved cartridge? You can rent the tools to rechamber your gun from our sister site: www.4drentals.com They stock all the popular Ackley chamberings and a few of the esoteric ones as well.

There is a book by the same title as this post, that tells you everything you need to know to properly headspace Ackley chambers. Click Here for more about the book.

I am a big Ack Fan

I have a very nice, very accurate, Mannlicher chambered in 7×57 AI. I’m trying to get reload data for it. I’m currently using 7×57 data and working them up. Got a stellar 139 grain and 154 grain load and am looking for a 162 grain load. Best so far is one inch at 100 yards. I’ve read that Sierra may have a pdf available from the original reload data but I haven’t tried that one yet (next).

Thank you for your time.

The book P.O. Ackley, America’s Gunsmith contains a large amount of load data from reputable sources and with pressure data. The simplest way to start loading for Ackley Improved Cartridges is to used reliable data for the parent cartridge as a starting point. You can safely start with top published loads for the parent as they use less powder than where you will finish with the AI chamber.

Personally, I look for pressure tested data for the parent, then I select the powder that used the lowest pressure to produce the highest velocity. This usually works out, but any reloader will tell you that not all barrels will shoot well with some combinations of components so plan to experiment.

https://ackleyimproved.com/product/p-o-ackley-americas-gunsmith/

Does anyone do this in 25-06? Is it possible to have it done to an Encore barrel?

If so, who does it, and where do you send correspondence?

Its a popular cartridge. It will work in an Encore too.

Mike Bellm TCs | Mike Bellm, US Mail: P.O. Box 276, UPS/Fed-Ex: 1525 E. 350 Rd, El Dorado Springs, MO 64744. Phone (541) 956-6938

Good luck with your project.

Waiting on the return of my Browning M71 – being turned into a 348 Ackley Improved.

P.O. Ackley is a national treasure!

Tim

I’m looking into getting a Steyr m95 in 8×56 RS Mannlicher and I was wondering if that round has ever been made into an Ackley Improved cartridge. It looks like that it would really benefit being made into an 8×56 RS Mannlicher AI round.

The round has a very sweeping neck design. If you blow out the neck forward to give you a neck of .329” long with a 40* neck with the shoulder diameter of .485 to .489” in diameter. You would have a very efficient round.

Since the .329” bullet isn’t that common, a better idea is giving it a .338” long neck and boring it out to the very common .338” bullet. Making it a .338×56 RS AI, giving it the power between the .338 Federal and the .338-06 A-Square. It would make a great medium to large game round using the 160gr TTSX to the 230gr bullet. It should work on antelope/deer to elk and eastern black bear that weigh 500-800lbs.

I am sure someone has done it at some point. It’s a cartridge with a limited following in the U.S.

No experience the the magazine in that gun, but It’s likely that it would work fine. It might be necessary how far you blow out the shoulder to make sure it works in the magazine.

Just a thought.

Can a 7.62×39 be made as well it would improve the ballistics drastically above 30-30

It probably has not caught on because depending on the shoulder diameter cases would likely split.

With a little experimentation it would certainly work just the shoulder would not be a big in diameter as some other cartridges?

I checked a couple of reamer makers and it is not in the standard list.

I have a 220 swift IMP P.O. Ackley gun was make in 1948 it has a model of 1917 Remington receiver. Gun was made for a rich man in Charlotte NC I was told it was make in the factory at Winchester by three WW2 veterans. Gun has the original Varmint Master scope still on it, It weighs17.5 pounds and gun shoots great.

Anyone know of any load data for 35 ackley magnum improved? Based on 375 h&h case necked down to .358

That would be very close to the 358 STA, if not identical if its the full length case. Just look at the STA and if you agree then starting loads for it will work fine for your version.

If its the shorter 338 Win length case, that would be a 358 Norma, same advice. Let us know.

As a reloader I will never have a 22-250 that isn’t A.I. it eliminates the case stretching that plagues the standard chamber.

Just aquired a German Drilling made by FW Kessler. Its a very nice piece with 16 ga double over a bbl that has been probably rechambered and stamped 316 Krag Ackley imp.. Any idea of what I have. Too nice to not use . Any help would be appreciated.

Sorry, I cannot help with that one.

Hello Admin

I’m looking for some help. though I think you have answered it in the above article. I have recently had a Fopen class rifle made in .260 AI. I have started to prepare Lapua .260 rem brass for fireforming and have noticed that when try to chamber a round I have to force the bolt closed. the chambering has a tight neck at .295 but I’m neck turning the cases so the loaded cartridge comes in at .292 . I presume that the tight chambering of the round is due to the .004 short headspace?

Just didn’t want to chance damaging the rifle or me prior to checking.

Hey John,

You should only feel slight resistance to the brass when closing the bolt. It may be that your chamber is headspaced a little too short.

You can check this with headspace gauges made for 308/243/7-08 Ackley improved family of chambers. The most common in the family is the 243 Win AI.

I am not sure if Lapua brass is thicker or extra hard? You might just need to anneal your cases. Hope all goes well.

Realizing this thread is over a year old…….

To John Stewart Downes:

Through my web surfing, I ran across your post. I cannot address your neck diameter involvement but:

I too have a 260 AI built by a local smith. I initially used new Rem260 brass (about all I could find in the ’05 era) and one box of store-bought 260 Rem ammo. Shortly after, I expanded into making 260AI brass from other cartridges, namely 308 Win, LC 7.62, and 7-08 Win.

My initial attempts at necking down with the 260AI dies resulted in collapsed cases. So, I purchased a set of RCBS standard 260 Rem dies. Using a standard 260 FL die worked OK. I set the die in the press to provide a “second shoulder’ on the larger parent case; such that I had a ‘crush’ feel when chambering the necked-down case. In my case, I feel the chamber was cut properly. Even so, it seemed that maximum sizing depth adjustment on the die/press installation, still left me with a very difficult bolt closure on some necked-down cases.

I solved the issue by having my smith take 30 thou (.030) off the end of the std sizing die. This allows me to adjust the die to size a case to any headspace length I need. I know not what dies you are using for case prep, but such a die modification might help your situation.

With all of the above being said, I purchased a box of Lapua 260 Rem cases and loaded them for FF’ing in this chamber. The first 5 cases FF’d (fireformed) formed nicely with no issues. I have since torn the gun down for stock replacement, but there were no issues fireforming the Lapua brass.

-FWIW, Howard

Without checking the gun I can only go by your comments. I would guess that your gun was headspaced incorrectly. You should be able to fire factory 260 Remington ammo with no difficulty.

I highly recommend this book to anyone working with Ackley Improved cartridges: https://4drentals.com/product/chambering-ackley-cartridge-booklet/